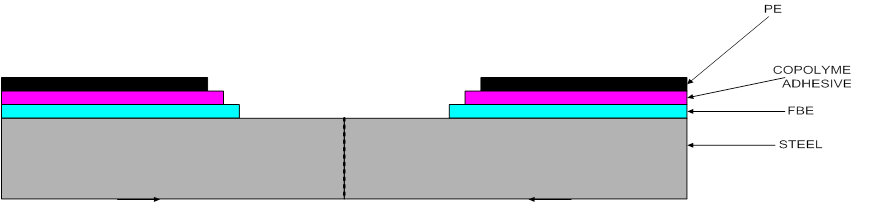

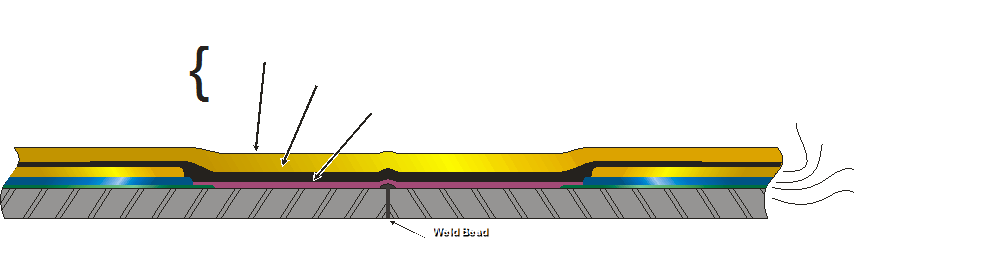

•3 layers

–Epoxy

–Adhesive

–Polyethylene

•Replication of mill-applied 3-layer PE coating

•Factory made design/system

Function of the intermediate adhesive

Maximise the adhesion to:

Polyethylene (Mechanical Protection) & Epoxy (Corrosion Protection)

Good shear resistance

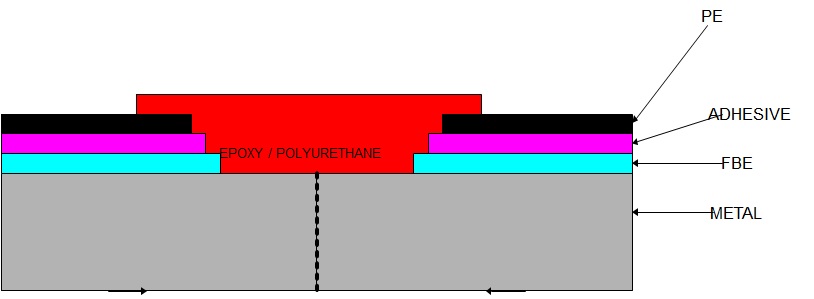

Sleeves

–Epoxy

–Adhesive

–Polyethylene

Reconstructs mill-applied coating performance

Liquids

Sole adhesive to bond to 4 materials:

–Steel

–Epoxy

–Adhesive

Polyethylene

•Adhesion Epoxy-Metal: 20-30MPa (ISO = 10 MPa)

•Adhesion PU-Metal:10-15 MPa (ISO = 10MPa)

•Adhesion PU / Epoxy - PE

•Not compliant with ISO 21809-3

•Adhesion of Heat Shrinkable Sleeves on Steel is the same as Adhesion on PE

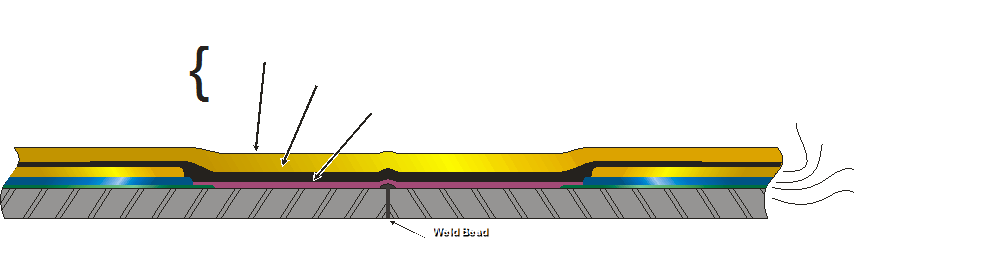

Line coating

determines the choice of girthweld protection.

Heat-Shrink

Sleeves

- PE 3 layers

- PP 3 layers

- FBE

- PU

Liquids (Epoxy/PU)

- FBE

- PU

Heat-shrink Sleeves

•Surface Preparation

•Pre-heating

•Mixing and application of Epoxy

•Sleeve Application

•Shrinking (Torch)

•Dielectric Testing (identical voltage)

(Irrelevant of the ambient conditions)

Liquids

•Applicator Protection (Spray)

•Prepare equipment (Spray)

•Surface preparation

•Pre-heating (especially PE)

•Appropriate mixing

•Roll or Spray

•Check and build up thickness (3 x 500 microns)

•Polymerization & Protection

•Dielectric Test (different voltages)

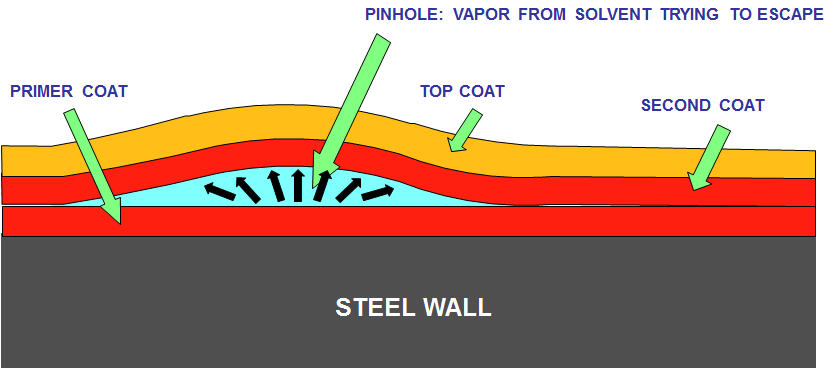

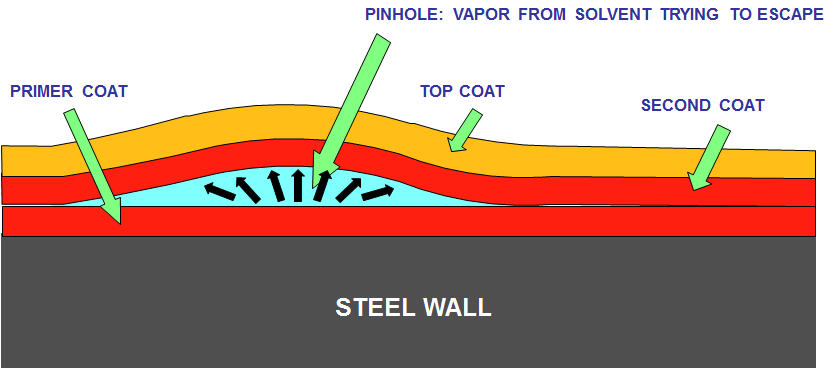

(Ambient Conditions RH < 80% to avoid Blistering)

Pinholes are a consequence of entrapped air and moisture

Welds / day (48”) : 50 - 170 (0,6 - 2km)

Sleeves

–Surface preparation (4-5min)

–Crew of 4 people

–6 joints / hour

–60 joints / day / crew

–1 crew for +/-50 joints

–3 crews for 170 joints

Easy logistics

Liquids

–Surface preparation (4-5min)

–3 passes (1500 microns)

–3 to 4 minutes coating interval

–10 to 15 minutes / joint

–40 joints / day / crew

–1 crew for +/-50 joints

–4 crews for 170 joints

Complex logistics

(Machine – product – storage – pot life)

Planning is driven by welding cycle time

Diameter: 48” – Cutback: 150mm

Sleeves

HTLP80 EN12608-UV

– Overlap: 50mm

– Thickness: 2,8 – 3 mm

– 100 / joint

Liquids

Epoxy Powercrete R60 & R95

–Overlap: 100mm

–Thickness: 1000-1500 microns

–Wastage: 50%

–5 liters (8kg) / joint

6-10US$/kg: 100-160 / joint

Polyurethane

–Overlap: 100mm

–Thickness: 1500 microns

–Wastage: 50%

–6 liters (9,6kg) / joint

5-6US$/kg: 100-120 / joint

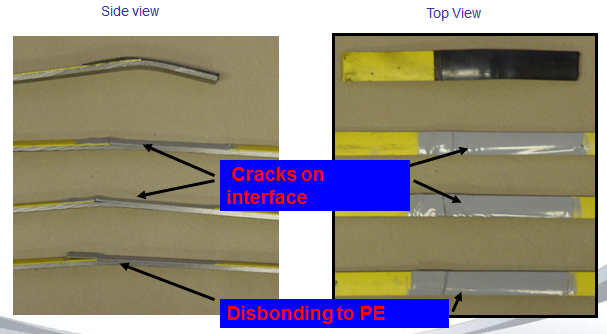

- Superior system: Adhesion to PE

- Compliant with international standards

- Does not cause delays (preference of contractors)

- Comparable budgets

This solution ensures the longest service life

Diameter: 48” – Cutback: 150mm

50 – 55 US$ / joint

Liquids

Epoxy Powercrete R60 & R95

–Overlap: 100mm

–Thickness: 1000-1500 microns

–Wastage: 50%

–5 liters (8kg) / joint

6-10US$/kg: 48-80US$ / joint

Polyurethane

–Overlap: 100mm

–Thickness: 1500 microns

–Wastage: 50%

–6 liters (9,6kg) / joint

5-6US$/kg: 48-58 US$ / joint