Fusion Splicer Fitel S183PMII V2

- Splicing specialty and exotic fiber combinations

- Very large diameter fiber splicing (up to 500µm)

- Polarization maintaining fiber splicing

- High-strength splicing application

- Fast splice time!

- Brand:Fitel Fusion Splicers

Code: MT00132X

| %%WISHLIST_DETAILS_BOX%% |

Features of ver.2

- Optimization of rotational adjustment for PANDA fiber

- Intuitive manual splicing

- Splicing dissimilar fiber mode

- Splicing various types of fiber ( Similar/Dissimilar, Dissimilar cladding, Polarization, High-strength, Very large diameter)

- Intuitive GUI interface

- Interlocking of measuring instrument

- Improving reliability and productivity for the manufacture of optical components

Features and applications

Specialty Splicing Mode Easy

The advanced features of the S183PMII allow you to splice today’s and tomorrow’s most exotic fiber types. Whether performing high-strength splices, splicing small cladding fibers (80 μm), large cladding fibers (500 μm), PM fibers or erbium doped fibers, the S183PMII is the splicer for your high-end application.

S183PMII automatically adjusts for different fiber coating and cladding sizes. There is no need to exchange v-grooves or fiber clamps. In addition, the S183PMII has been designed so that the user simply loads the fiber and closes the lid to begin the splice process. There is no need to lower or set fiber clamps before starting to splice.

S183PMII automatically performs a tensile proof test on the fiber and releases the holder lid to avoid twisting the fiber after the splice. This automation eliminates the need for the user to manually open and reset the splicer after each fusion splice.

How is Fiber Optic Splicing done?

Fusion splicing is using localized heat to melt or fuse the ends of two optical fibers and connect them with each other. The splicing begins by getting each fiber end ready to be fused.

Fiber Stripping before Splicing

The protective coating made of polymer surrounding the optical fiber has to be removed in order for it to be ready for fusion splicing. When both fiber ends for fusion are ready the splicing can be started, each fiber should first lose its protective coating. Using a fiber stripper, all that can be done easily.

Fiber ends cleaning

Any dust or particles on the end of the optic fiber can affect the light signal or even block it. After the two ends are fused together through the splicing process, no dust or anything, not even air, should be inside the linking point.

Fiber optic Cleaving

Cleaving means cutting the edges of the fiber ends in order to ensure that each in 90° degree to fiber; when the two end meet they should be perfectly flat and touching each other completely.

Actual Fiber Splicing Step

Just put the two fiber ends into the splicer and start the fusion when they are in complete contact, then the machine runs a test to ensure the splice will survive long time usage and that the light loss at the splice is at minimum. The best result should be 00.00 dB, which means the splicing was perfect.

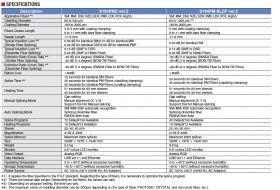

| Alignment Type: | Core Alignment |

|---|---|

| Applicable Fiber: | SM / MM / DSF / CSF / PMF / LDF |

| Fiber Count: | Single Fiber |

| Cladding Diameter: | 80 to 500 μm |

| Coating Diameter: | Single: 160 - 2000 μm |

| Cleave Length: | 9-11 mm - Normal Strength 3-5 mm - High Strength |

| File | Info |

|---|---|

S183PMII-S184PM_Fitel_Datasheet S183PMII-S184PM_Fitel_Datasheet | [PDF, 2.28 MB] |