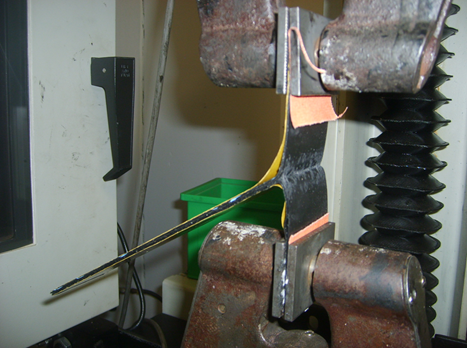

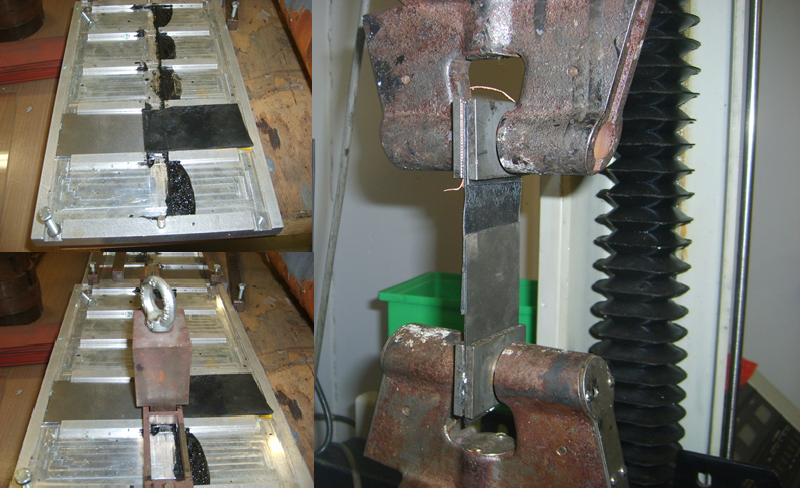

4. Peel Strength to pipe surface and main coating (@23°C & 10mm/min)

Heat Ageing: 70 & 100 days

(Tmax+20°C)

EN12068

A100/At>0,75 & A100/A70>0,8

ISO21809-3 (3LPE&3LPP)

A100/A0>0,75

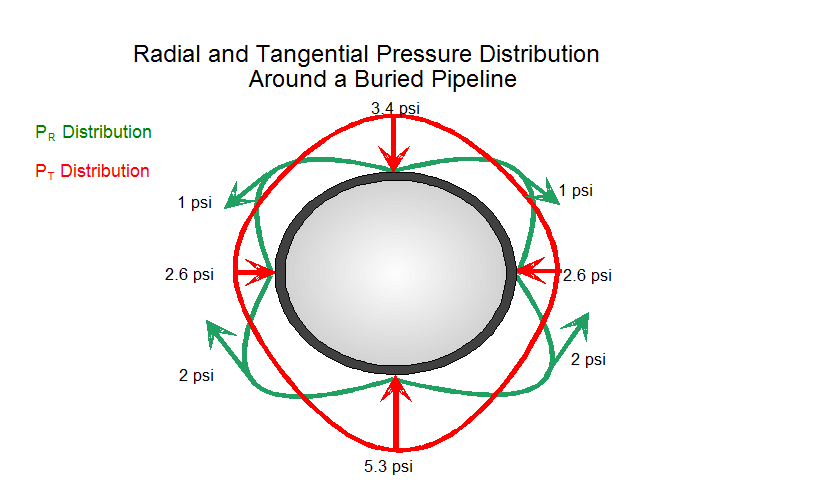

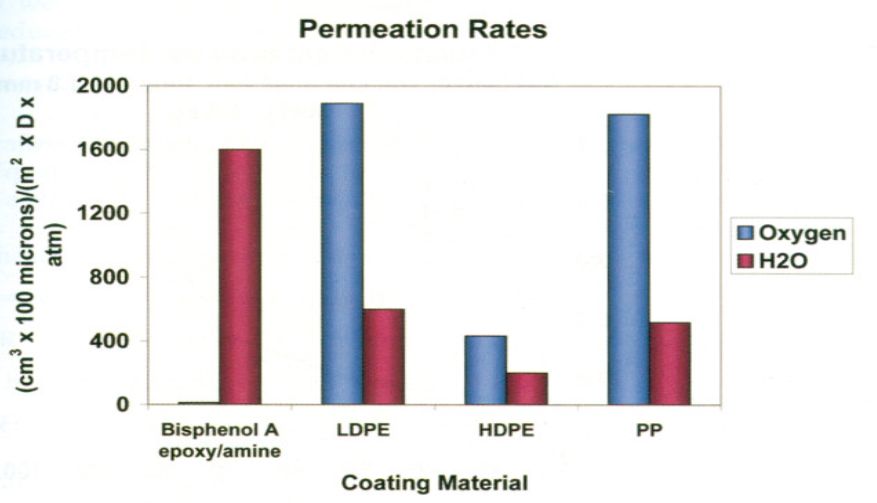

28 days Hot on MAX Water Immersion Permeation of Moisture & Oxygen

EN12068

No Test

ISO21809-3 (3LPE & 3LPP)

Pipe Coating

3LPE: 1,5N/mm 1,5N/mm

3LPP: 2,0N/mm 2,0N/mm

5. Peel Strength Layer to Layer

(@23°C & 100mm/min – inner/inner – inner/outer)

EN12068

Class A: 0,8N/mm

Class B: 0,8N/mm

Class C: 1,0N/mm (if CD: 10mm)

Class C: 1,5N/mm (if CD: 15mm)

Class C: 1,5N/mm (if CD: 20mm)

ISO21809-3 (Polymeric Tapes)

50°C 80°C

1,5N/mm 1,5N/mm

70 & 100 days in oven

(Tmax+20°C)

EN12068

P100/Pt>0,75

P100/P70>0,8

ISO21809-3

50°C 80°C

P100/P0>0,75 P100/P0>0,75

P100/P70>0,8 P100/P70>0,8

5. Lap shear Strength

EN12068 @23°C & @TmaxC

Class A: 0,05N/mm²

Class B: 0,05N/mm²

Class C: 0,05N/mm² (if CD: 10mm)

Class C: 0,05N/mm² (if CD: 15mm)

Class C: 0,05N/mm² (if CD: 20mm)

ISO21809-3 (3LPE&3LPP)

@23°C @TmaxC

3LPE: 1,0N/mm² 0,07N/mm²

3LPP: 2,0N/mm² 0,5N/mm²

7. UV Resistance

Continuous irradiation

of a xenon lamp:

Contents

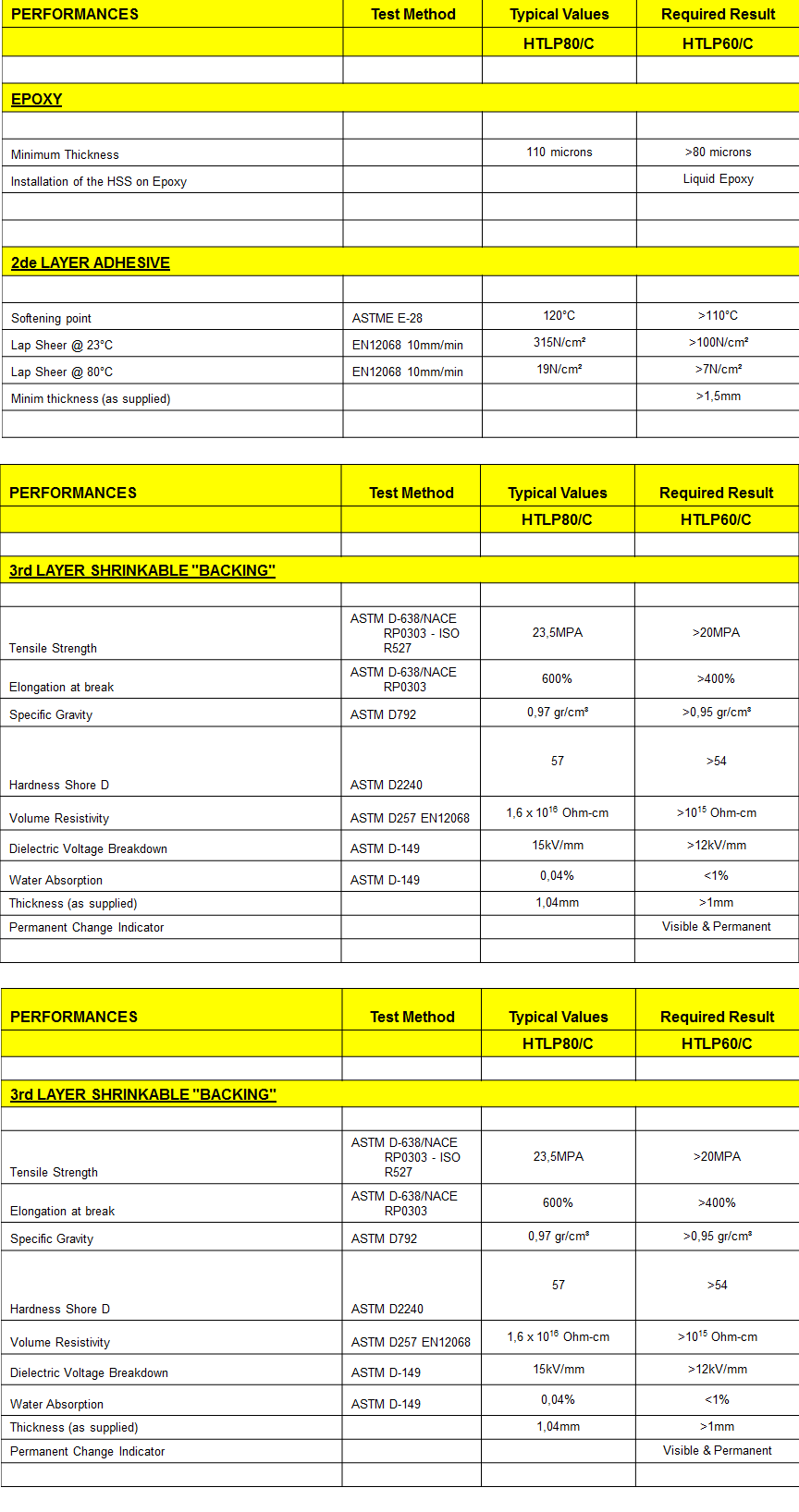

Liquid Epoxy

- Sand blasting

Epoxy Thickness

- Surface preparation SA2 ½

- Profile 50 – 100 microns

- Epoxy Thickness: 80 – 110 microns

Thicknesses

- Epoxy Thickness: >0,1mm

- Adhesive Thickness (hotmelt): 1,5mm

- Backing Thickness (as supplied): 1 – 1,04mm

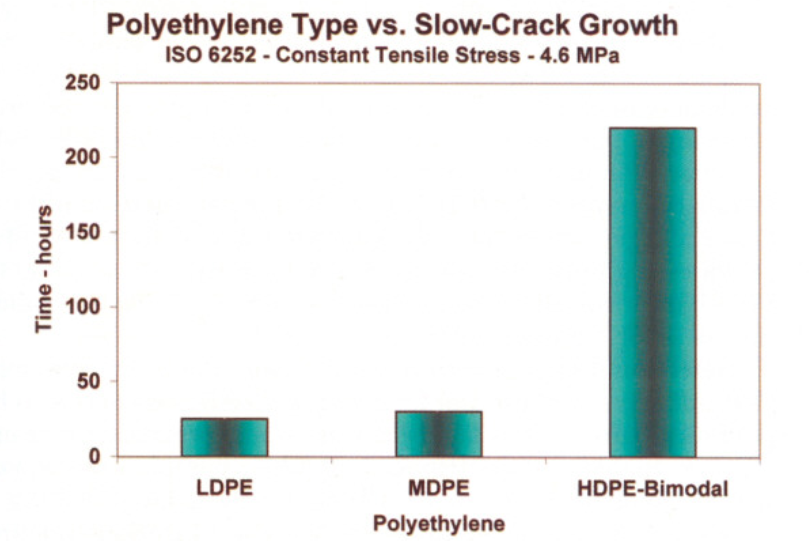

Density of Polyethylene

High Density Polyethylene

<<What is the difference between heat shrink sleeves (HSS) and other joint coatings? (1/2)