Contents

ISO 21809-5 External Concrete Coatings

Standards for Field Joint Coating

1979 – 1999:

1998 - 2008:

- Cold Tape & Heat Shrinkable Sleeves

- No Temperature limitation

- Cathodic Disbondment test

- UV test

- Mechanical resistance (Class A, B & C)

- Class C: 3 peel values in Function of CD test

2009 +

- All technologies:

- Bituminous, Petrolatum, Wax & Polymeric Tapes

- Heat Shrinkable Coatings (Tapes & Sleeves - 2LPE-3LPE-3LPP)

- Fusion Bond Epoxy (FBE)

- Liquid Coatings (Epoxy & Polyurethane)

- Others (Polyolefin, Thermal Spray Aluminium, Hot Wax, Elastomeric)

- Requirements:

- 1 Class mechanical resistance

- Test methods = EN & ASTM

Contents

Test Methods & Requirements

1. Impact Resistance:

EN12068

Class A: 4J

Class B: 8J

Class C: 15J

Test 5kV/mm

ISO21809-3

3LPE: 5J/mm

3LPP: 8J/mm

Test 5kV+5kV/mm

.jpg)

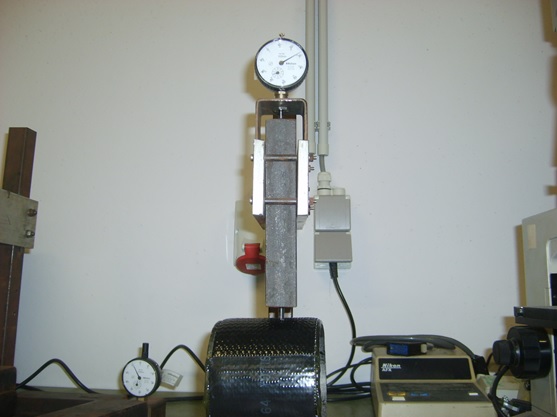

2. Indentation Resistance: (@23°C)

EN12068 (72 hours)

Class A: 0,1N/mm²

Class B: 1,0N/mm²

Class C: 10N/mm²

Test 5kV/mm or Thick: 0,6mm

ISO21809-3 (3LPE&3LPP) (24 hours)

50°C: 1,0N/mm²

120°C: 10N/mm²

Test 5kV+5kV/mm & Thick: 0,6mm

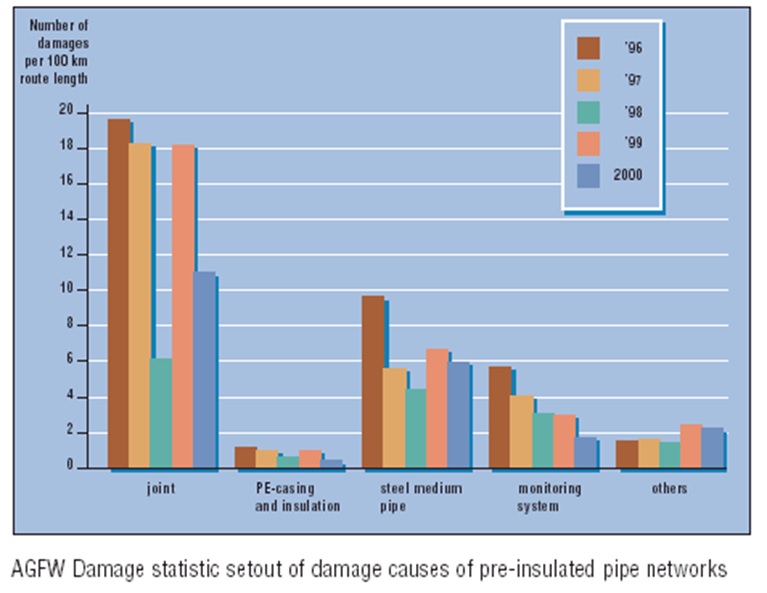

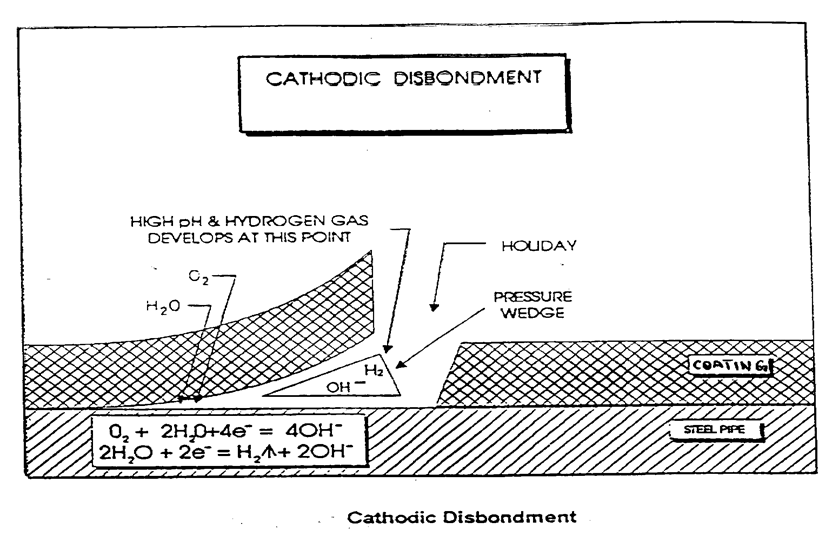

3. Cathodic Disbondment Resistance

.png)

EN12068 (28 days @ 23°C)

Class A: 20mm

Class B: 20mm

Class C: 10-15-20mm

@Tmax: no requirement

ISO21809-3 (3LPE&3LPP) (28 days)

@23°C: 8mm

@Tmax (95°C): 15mm

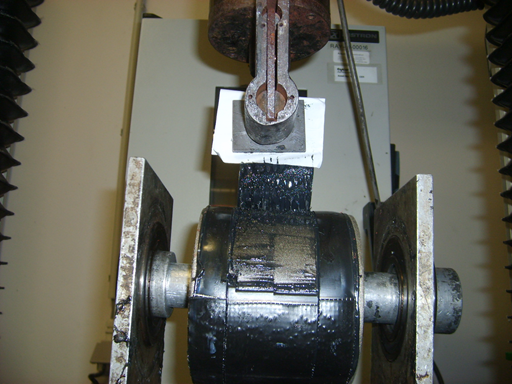

4. Peel Strength to pipe surface and main coating

4. Peel Strength to pipe surface and main coating (@23°C & 10mm/min)

EN12068 Pipe Coating

Class A: 0,4N/mm 0,2N/mm

Class B: 0,4N/mm 0,2N/mm

Class C: 0,5N/mm 0,4N/mm (if CD: 10mm)

Class C: 0,75N/mm 0,4N/mm (if CD: 15mm)

Class C: 1,0N/mm 0,4N/mm (if CD: 20mm)

ISO21809-3 (3LPE&3LPP)

Pipe Coating

3LPE: 2,5N/mm 2,5N/mm

3LPP: 4,0N/mm 4,0N/mm

.png)