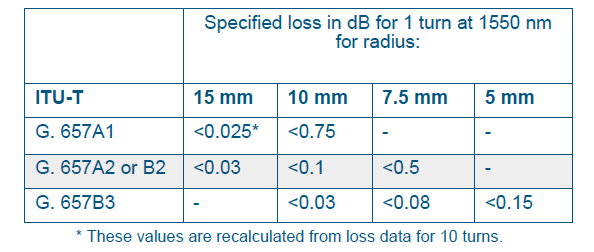

Specified bending losses in new ITU-T G.657

4 classes defined in the new ITU-T G.657 (be aware that this is still a draft!):

G. 657A1: these are G. 652D compatible fibers with specified minimum bending radius of 10 mm (same as previous G.657A)

G. 657A2: these are G. 652D compatible fibers with specified minimum bending radius of 7.5 mm

G. 657B2: these are not G. 652D compatible fibers with specified minimum bending radius of 7.5 mm

(same as previous G. 657B)

G. 657B3: these are not G. 652D compatible fibers with specified minimum bending radius of 5 mm

Mechanical reliability concerns

- During production fibers are screened with a 1% strain (or 0.7 GPa or 100 kpsi) test.

- A fiber bend with a 6 mm radius will have about 1% strain stress at the outside of the cladding.

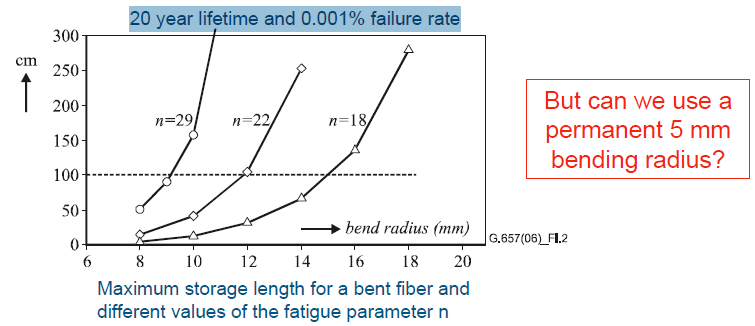

- The new ITU-T G.657 proposal document also deals with fiber lifetime considerations (in Annex I). Important :The accepted probability for fiber failures in the FTTH distribution part is around 1/100000 over 20 years per fiber per network element. However, the document does not state that a 5 mm storage radius can be used in a reliable way! Knowledge of the network layout is very important when deploying such low storage radii.

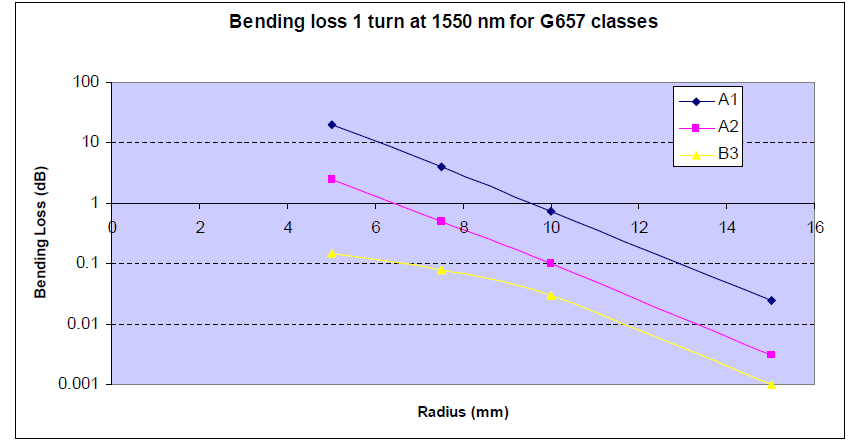

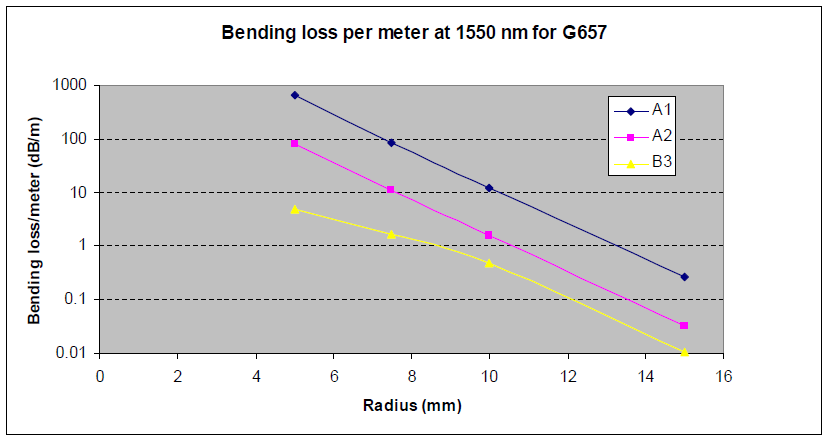

Specified bending loss values in ITU-T G.657

Mechanical reliability concerns – ITU-T G.657 Annex I

In the datasheets for fibers a parameter n is specified (n= the stress-corrosion susceptibility parameter or fatigue resistance parameter). This parameter is derived from a log (stress) versus a log (% cumulative failure) plot. The IEC 60793-2-50 standard for fibers specifies a minimum value of 18. Corning SMF28+ specified n=20 (which means better resistant to longterm bending)

In ITU-T G.657: Annex I

20 year lifetime and 0.001% failure rate

Mechanical reliability concerns

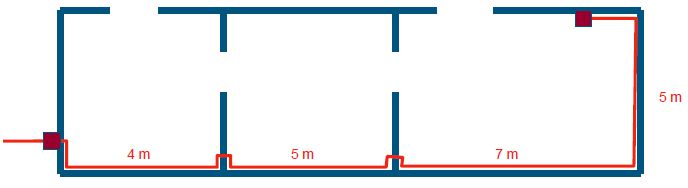

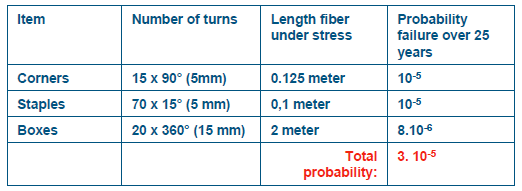

Installation inside houses:

Assume cable is routed though 3 rooms on the 1st floor:

- This results in about 15x 90° turns around a corner

- When nails or staples are used every 30 cm, about 70 staples will be used in this example. Assume that each staple or nail creates a bend with radius 5 mm over 15°

- In total 2 meter of fiber is stored in the floor distribution box and wall terminal with radius 15 mm

Important:

Important:

- In this case the estimated contribution of bending loss will be 1 dB at 1550 nm and 3 dB at 1625 nm for a G 657 B3 fiber!

- Influence on axial tension in fibers is NOT taken into account!

Low Optical Bend Loss Fibers

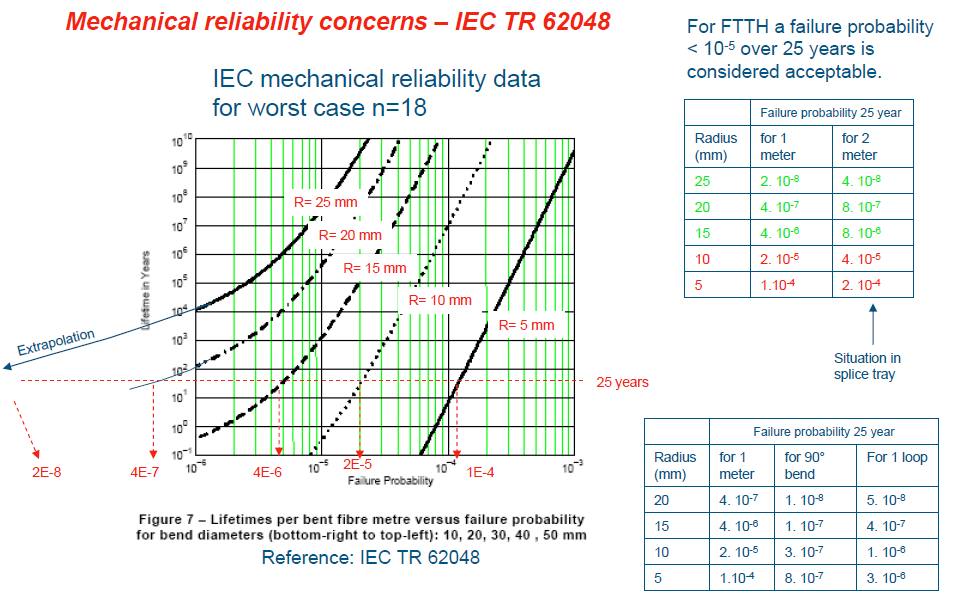

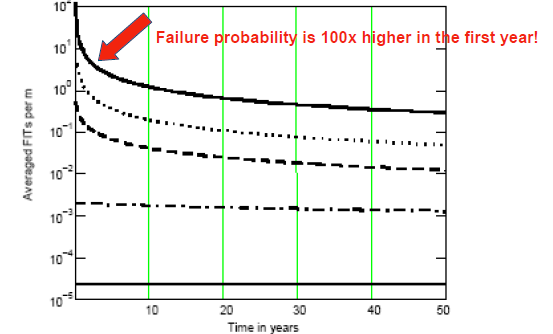

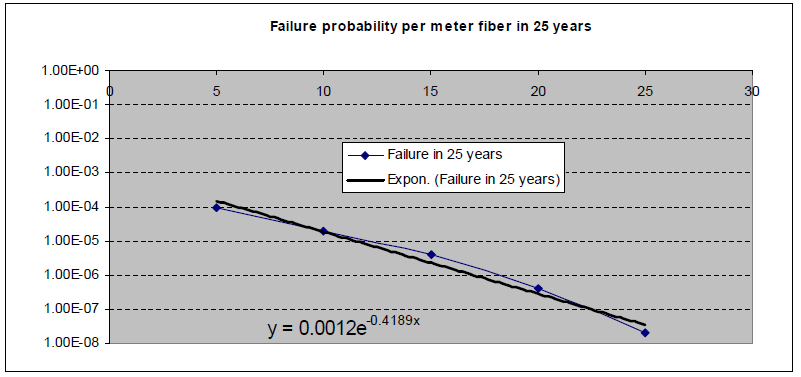

For FTTH network elements a failure probability < 10-5 over 25 years is considered acceptable, but failure rate is not constant for small bend radii over 25 years!

Reference: IEC TR 62048

What are the best design rules for fiber management systems for such fibers?

Mechanical and optical reliability concerns

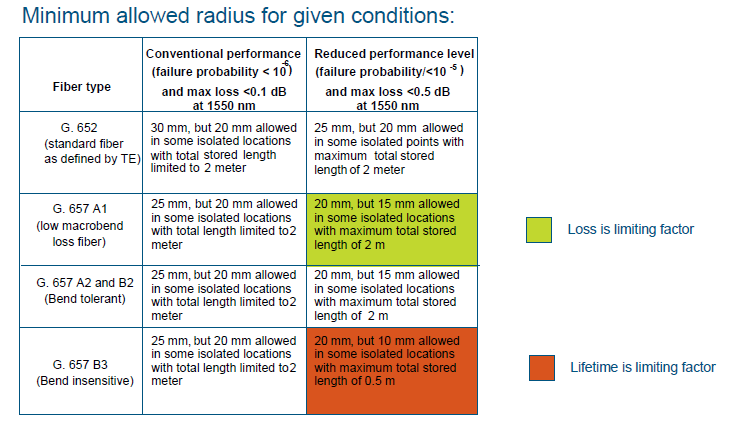

Relationship between radius, stored length, bending loss and mechanical reliability.

When using the data from IEC TR 62048 the failure probability as function of the stotage radius can be calculated

Mechanical and optical reliability concerns

Relationship between radius, stored length, bending loss and mechanical reliability.

When using the bending loss performance specified in ITU-T G657 the following maximum loss estimates per fiber class (A1, A2, B3) can be made:

Mechanical and optical reliability concerns

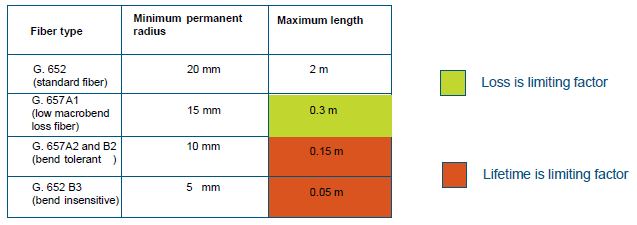

Simplified design rules for fiber management system that stores 2 meters of fibers per splice (without axial tension):

Minimum allowed radius for given conditions:

Mechanical and optical reliability concerns

Reliability in indoor FTTH installations

- From a mechanical reliability point of view the installation rules for indoor cabling can be:

- Bend around corners: Up to 15x 90° bends around a corner with 5 mm radius.

- Staples or nails: 70x is possible when radius of fiber under staple is limited to 5 mm minimum.

- Loops of cable (over length cable) shall be made with the largest of the following 2 values: value in previous table or 10x cable diameter.

- Axial tension on cable (30% of proof strain level = max specified load for cable)

Taking the optical (loss <0.5 dB at 1550 nm) AND mechanical (failure rate<10-5per meter) limitations into account the following general cable installation rules will apply

Issues seen with bend insensitive fibers

- Some fusion splicing machines do not recognize the core of the new fibers and will not perform a core alignment (switch to cladding alignment to solve this)

- Hole assisted fiber types give problems during fusion splicing (unexpected and unpredictable deformations). Fluids may enter the holes when cleaning the fiber ends with alcohol

- Higher losses seen when different fiber types are spliced or connected together (mode field diameter mismatch with most G. 657B type fibers). Losses above 1 dB can be seen!

<<Update on optical fiber and cable standards(1/3) Update on optical fiber and cable standards(3/3)>>